Introduction:

Sewage trucks, also known as vacuum trucks or cesspool emptiers, play a vital role in maintaining public health and sanitation by collecting and transporting wastewater and sewage. These specialized vehicles are equipped with various components that enable efficient and safe operations. In this comprehensive guide, we will explore the essential components of a sewage truck, highlighting their functions and importance in the overall functionality of these vehicles.

- Vacuum System:

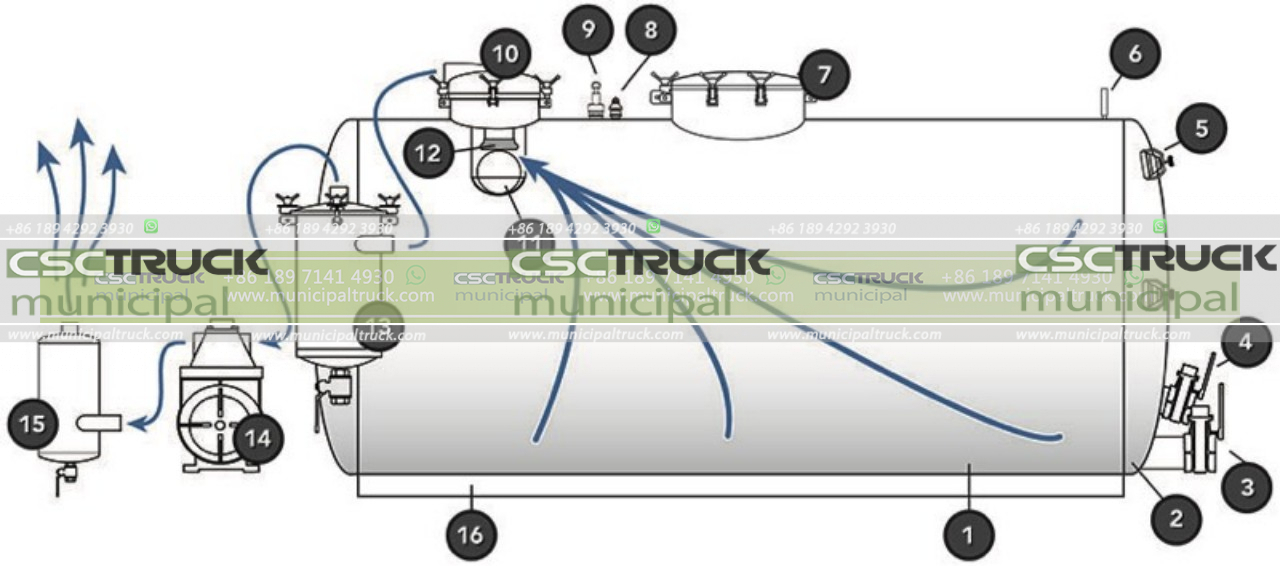

The vacuum system is the heart of a sewage truck, responsible for creating suction and extracting wastewater from septic tanks, cesspools, and other waste storage units. It consists of a powerful vacuum pump, typically powered by the truck’s engine, which generates negative pressure to draw in the sewage. The vacuum system also includes a series of hoses, valves, and fittings that connect to the storage tank for efficient suction and discharge operations.

- Storage Tank:

The storage tank is where the collected sewage is stored during transportation. It is typically made of durable materials such as steel or aluminum to withstand the corrosive nature of the waste. The tank’s capacity can vary depending on the truck’s size and purpose, ranging from a few hundred gallons to several thousand gallons. To ensure safety and prevent leaks or spills, the tank is equipped with secure seals, access ports for cleaning and maintenance, and liquid level indicators.

- Dumping Mechanism:

Once the sewage truck reaches its designated disposal site, the dumping mechanism is used to unload the collected waste. Different types of dumping mechanisms are employed, including hydraulic lift systems or tipping tanks. These mechanisms allow controlled and efficient discharge of the sewage while minimizing the risk of spills or contamination. Safety features such as locks and latches are incorporated to secure the dumping mechanism during transportation.

- Water Supply System:

Sewage trucks often require water for various purposes, such as cleaning the tanks, flushing the hoses, or diluting the waste to facilitate transportation. The water supply system consists of a water tank, a pump, and a network of pipes and nozzles. The water tank, typically separate from the sewage storage tank, holds clean water that can be used when needed. The pump pressurizes the water, allowing it to be sprayed through the nozzles for cleaning and rinsing operations.

- Filtration and Separation Systems:

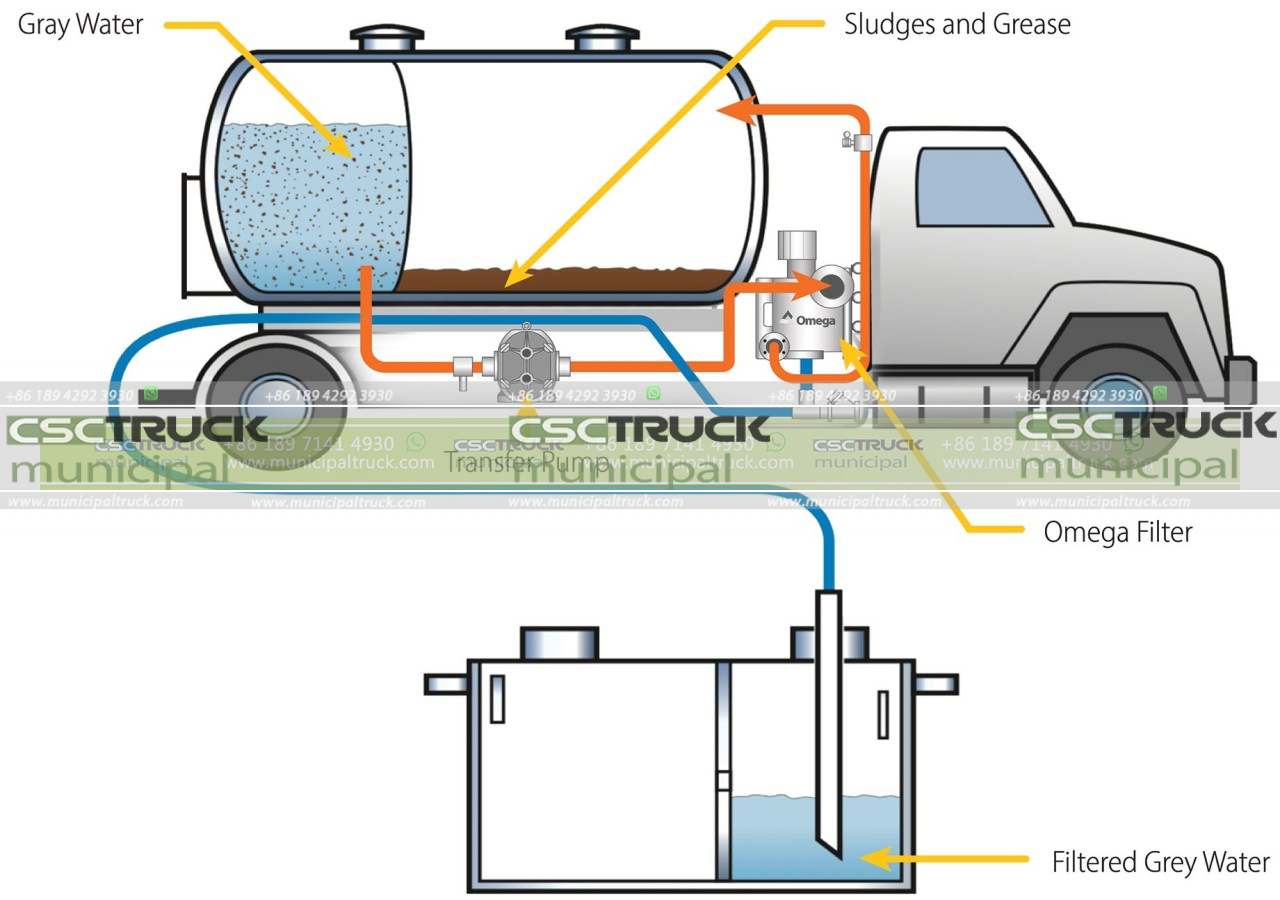

To ensure efficient operation and protect the vacuum system, sewage trucks employ filtration and separation systems. These systems remove large debris, solids, and liquids that could damage the pump or contaminate the surrounding environment potentially. Filters, screens, and separators are strategically placed within the suction and discharge lines to trap solid particles and separate liquid components, allowing only wastewater to enter the storage tank.

- Control Panel and Instrumentation:

The control panel and instrumentation provide the operator with vital information about the sewage truck‘s performance and enable control over its various functions. The panel includes switches, gauges, and indicators that monitor the vacuum pressure, water level, temperature, and other critical parameters. This information helps the operator maintain optimal operating conditions and identify any potential issues that may require attention or maintenance.

- Safety Features:

Given the nature of their operations, sewage trucks are equipped with several safety features to protect both the operators and the environment. These features include emergency shut-off switches, spill containment systems, and safety alarms. Emergency shut-off switches allow the operator to quickly stop the vacuum pump in case of an emergency. Spill containment systems prevent sewage leaks or spills during transportation, while safety alarms alert the operator to any abnormalities or malfunctions.

Conclusion:

Sewage trucks are indispensable in maintaining public health and sanitation by collecting and transporting wastewater and sewage. The essential components discussed in this comprehensive guide form the backbone of these specialized vehicles, ensuring efficient and safe operations. From the vacuum system and storage tank to the dumping mechanism, water supply system, filtration and separation systems, control panel, and safety features, each component plays a crucial role in the functionality of a sewage truck.

Efficient suction and discharge of sewage are made possible by the vacuum system, which creates negative pressure to extract waste from storage units. The storage tank, designed with durability and safety in mind, securely holds the collected sewage during transportation. The dumping mechanism, whether it’s a hydraulic lift or tipping tank, facilitates controlled unloading of the waste at designated disposal sites.

.jpg)

Water supply systems are essential for cleaning and maintenance purposes. These systems provide a source of clean water that can be used for rinsing tanks, and hoses, and diluting the waste if necessary. Filtration and separation systems protect the vacuum pump and prevent contamination by removing large debris, and solids, and separating liquids from the waste.

.jpg) The control panel and instrumentation give operators crucial information about the truck’s performance, such as vacuum pressure, water level, and temperature. This data allows them to maintain optimal operating conditions and address any potential issues promptly. Safety features, including emergency shut-off switches, spill containment systems, and alarms, are incorporated to ensure the safety of operators and prevent environmental damage.

The control panel and instrumentation give operators crucial information about the truck’s performance, such as vacuum pressure, water level, and temperature. This data allows them to maintain optimal operating conditions and address any potential issues promptly. Safety features, including emergency shut-off switches, spill containment systems, and alarms, are incorporated to ensure the safety of operators and prevent environmental damage.

In addition to these essential components, sewage trucks may also include additional features such as storage compartments for equipment and tools, lighting systems for nighttime operations, and specialized attachments for specific tasks. These additional components enhance the functionality and versatility of the sewage truck, allowing operators to perform their duties more efficiently.

Regular maintenance and inspection of all components are crucial to ensure the proper functioning of sewage trucks. This includes routine checks of the vacuum system, storage tank integrity, dumping mechanism, water supply system, and filtration systems. Operators should also monitor and maintain the control panel and instrumentation to ensure accurate readings and optimal performance.

In conclusion, sewage trucks are vital vehicles for maintaining public health and sanitation. Understanding the essential components of these trucks is crucial for operators and maintenance personnel. The vacuum system, storage tank, dumping mechanism, water supply system, filtration and separation systems, control panel, and safety features all work together to ensure efficient and safe operations. By adhering to proper maintenance practices and employing the necessary safety measures, sewage trucks can continue to play a significant role in waste management and environmental protection.

Contact us for this municipal truck or similar trucks: [email protected] Call us or What's APP us: +86 189 4292 3930